Turtlebrace for wrist

Turtlebrace for wrist

Direct molding immobilization brace, for the ankle, made with low temp thermoplastic core.

Products

An “apply and forget” type brace made of stratification of multi-perforated low-temperature thermoplastic and a microfiber fabric.

The great flexibility of the components stabilizes the joint more easily, and with more precision, than a traditional brace or cast.

It can be reshaped many times, without losing its qualities; allowing adjustment according to the loss of swelling or morphological changes.

Characteristics

- Direct molding on the limb

- Antibacterial fabric

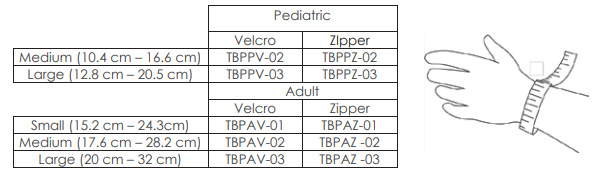

- Ambidextrous, it comes with Velcro or zipper closure

- Radio-transparent

- Submersible and auto-draining

- Re-moldable without limits nor degradation

- 3.2 mm thickness that permits normal dressing

- Compostable eco-friendly plastic

Classification

Single patient, non-sterile, non-measuring class 1 medical device

Indications

Stable fractures, sprains, post-op immobilization, carpal tunnel, tendinitis, serial casting, spasticity control, wrist, and hand neuropathy.

Models

Molding instructions

- Heat, the brace in an oven or hot water pan, between 67 °C and 85 °C (152°F and 185°F), until it becomes soft and elastic.

– Dry heat method: Put the brace in either the Turtlebrace heating bag, a regular or convection oven, for about 5 minutes.

– Hot water method: Place the brace in a hot-water heating pan for about 3 to 5 minutes. - Once the brace has become soft and elastic, you can drape the brace on the body. Make sure that the temperature of the brace is not too hot for comfort or at risk of burning your patient.

- Place your patient in the desired position and wait for the brace to harden. Once hardened, the brace will keep its shape until you heated back again.

Precaution of use

Do not drape the brace if it is too hot to avoid skin burns or discomforts.

Do not heat the brace over 100°C (210°F), because the fabric or/and the zipper could burn or melt.

If you use a heat gun, be careful not to burn the fabric.